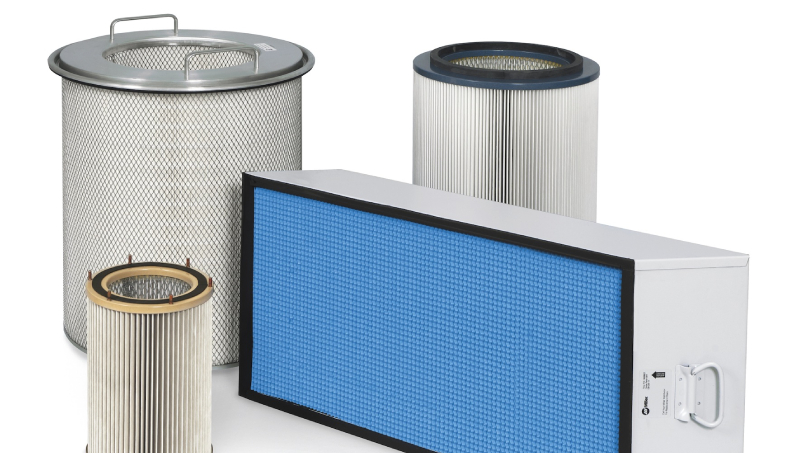

FILTER

Aluminum Application in the Filter Industry

The filter industry plays a critical role in the cleaning and purification of air, water and other liquids. Aluminum is one of the preferred materials in filter production and is widely used in this field thanks to the various advantages it offers. Here are the main applications and benefits of aluminum in the filter industry:

Lightness and Durability

Aluminum is a lightweight material and also has high durability. This feature makes it easier to transport and install filters, while ensuring their longevity. Aluminum filters can be used for a long time, withstanding harsh conditions.

Resistance to Corrosion

Aluminum is a naturally corrosion-resistant material and does not deteriorate when in contact with water and other liquids. This is a great advantage, especially for water filters and chemical filters. Aluminum increases the reliability of filters, reducing maintenance and replacement costs.

High Heat Resistance

Aluminum is a material that can withstand high heat. This feature is especially important in industrial applications, in the production of filters that work with hot gases and liquids. Aluminum filters perform effectively even at high temperatures.

Aesthetics and Design Flexibility

Aluminum can be processed into different shapes and sizes. This allows filter designers to develop creative solutions. Aluminum filters can also look aesthetically pleasing, which makes them preferred for modern applications.

Easy Cleaning and Maintenance

Aluminum filters can be easily cleaned thanks to their smooth surfaces. This simplifies maintenance processes and extends the life of the filters. Cleanable aluminum filters help users reduce costs.

Recycling and Sustainability

Aluminum offers an environmentally friendly option as a recyclable material. After-use aluminum filters can easily be recycled and used in the production of new products. This helps preserve natural resources and reduce waste.